The Ultimate Guide to Understanding the Pi123 Valve

Have you ever wondered what makes the Pi123 valve such a crucial component in various industries?

From its basic functionality to its significance in different applications, understanding this valve can greatly impact your operations.

As you navigate through this guide, you will gain valuable insights into the key components, maintenance practices, and even potential future developments of the Pi123 valve.

So, are you ready to explore the intricacies of this essential industrial tool and enhance your knowledge?

The Basics of the Pi123 Valve

The Pi123 Valve is a crucial component in many industrial systems, regulating the flow of fluids and gases with precision and reliability. This valve operates by using a rotary motion to control the flow of media through a system. It’s designed to handle a wide range of pressures and temperatures, making it suitable for various applications across different industries.

One of the key features of the Pi123 Valve is its ability to provide accurate and repeatable flow control. This means that you can rely on this valve to maintain consistent flow rates, which is essential for ensuring the efficiency and reliability of your industrial processes.

In addition, the Pi123 Valve is known for its durability and longevity. Constructed from high-quality materials, it’s designed to withstand the rigors of industrial environments, making it a dependable choice for your systems.

Furthermore, the Pi123 Valve offers ease of maintenance, with simple disassembly and reassembly procedures, allowing for quick and hassle-free servicing when needed. This ensures minimal downtime and optimal performance for your industrial operations.

Understanding the Functionality

Now that you grasp the robustness and reliability of the Pi123 Valve, let’s dive into its functionality and how it precisely controls the flow of fluids and gases in industrial systems.

The Pi123 Valve’s functionality is based on a precision-engineered design that enables it to regulate the flow of liquids and gases with remarkable accuracy. The valve’s internal components, including the actuator, seat, and sealing elements, work in harmony to ensure precise control over the flow rates and pressures within industrial processes.

One key aspect of the Pi123 Valve’s functionality is its ability to modulate flow rates in response to varying system demands. This means that the valve can adjust the flow of fluids and gases in real-time, maintaining optimal operating conditions within the industrial system. Additionally, the valve’s design allows for quick response times, enabling it to react swiftly to changes in flow requirements.

Furthermore, the Pi123 Valve is designed to provide reliable shut-off capabilities, ensuring that the flow of fluids and gases can be completely halted when necessary. This feature is crucial for safety and maintenance purposes within industrial environments.

Applications in Different Industries

With its versatile design and precise control capabilities, the Pi123 Valve finds extensive application across various industries.

In the oil and gas sector, the valve’s ability to handle high pressures and temperatures makes it ideal for controlling the flow of crude oil, natural gas, and refined products. Additionally, its reliability in harsh environmental conditions ensures uninterrupted operations in offshore drilling platforms and onshore facilities.

In the chemical industry, the Pi123 Valve’s corrosion-resistant materials and accurate flow control enable it to manage the precise handling of various chemicals and acids.

It’s also widely utilized in the pharmaceutical industry for its ability to maintain sterile conditions and regulate the flow of different fluids during the production process.

Furthermore, in the water and wastewater treatment industry, the Pi123 Valve’s efficiency in managing the flow of liquids and its resistance to corrosion make it an essential component in the treatment and distribution of clean water, as well as the management of wastewater.

Its versatility and precision control capabilities make it a valuable asset in a wide range of industrial applications.

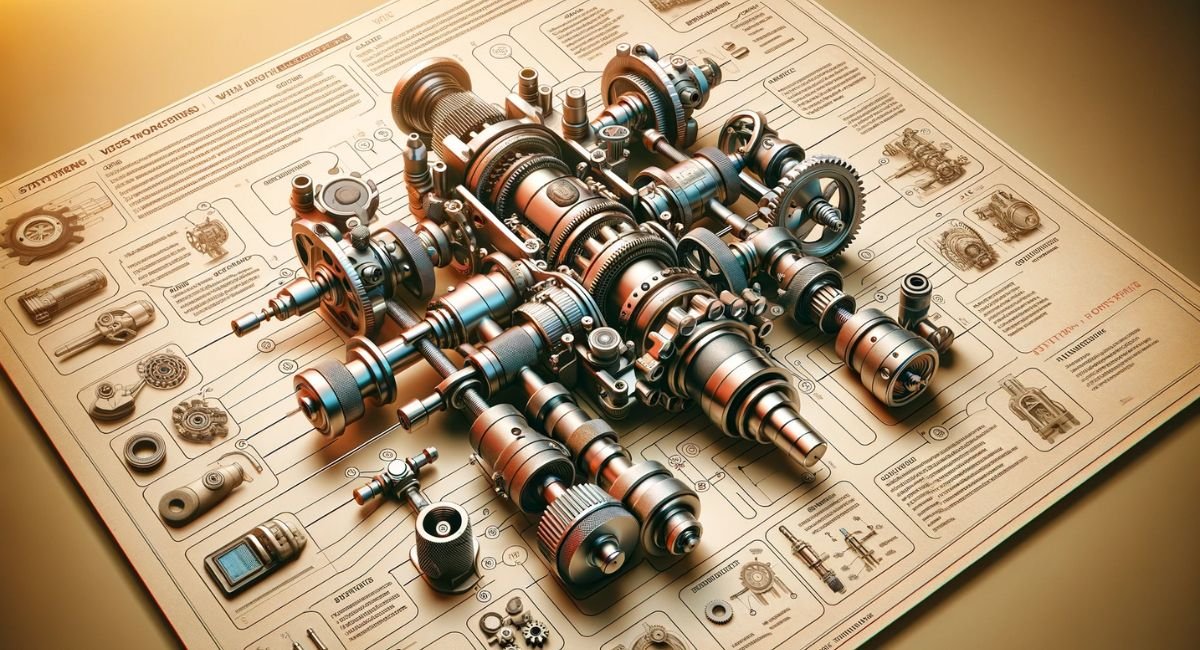

Key Components and Parts

Key Components and Parts play a crucial role in the overall functionality and performance of the Pi123 Valve. The valve consists of several key components, each with its specific function.

The body of the valve serves as the main pressure boundary and fluid passage. It’s designed to withstand high pressures and temperatures.

The actuator is another essential part, responsible for controlling the opening and closing of the valve. It can be pneumatic, electric, or manual, depending on the application’s requirements.

The trim, which includes the disc, seat, and other internal components, regulates the flow of the fluid through the valve. Proper selection and maintenance of the trim are critical for optimal performance.

Additionally, the bonnet provides a cover for the valve body and houses the stem and other internal parts. Seals and gaskets ensure tight shut-off and prevent leakage.

Understanding the function and importance of these key components is essential for maintaining the Pi123 Valve’s efficiency and reliability.

Importance of Proper Maintenance

Proper maintenance of the Pi123 Valve’s key components and parts is essential for ensuring its continued efficiency and reliability. Regular maintenance helps prevent unexpected breakdowns and costly repairs. It also extends the lifespan of the valve, saving you time and money in the long run.

By following the manufacturer’s recommended maintenance schedule, you can ensure that the valve operates at peak performance, delivering accurate and consistent results. Neglecting maintenance can lead to issues such as leaks, reduced flow capacity, and compromised safety.

Routine inspections and cleaning of the valve components are crucial to prevent the accumulation of debris and corrosion, which can hinder the valve’s functionality. Additionally, lubricating moving parts and replacing worn-out seals are vital for optimal performance.

Proper maintenance also ensures that the valve complies with industry regulations and standards, promoting a safe working environment. Ultimately, investing time and resources in the regular upkeep of the Pi123 Valve will maximize its efficiency, minimize downtime, and contribute to overall operational success.

Troubleshooting Common Issues

To effectively troubleshoot common issues with the Pi123 Valve, thoroughly inspecting all components is crucial for identifying potential problems and implementing appropriate solutions.

Start by checking for any visible signs of damage or wear on the valve body, seals, and connections.

Next, ensure that the valve is receiving the correct input pressure and that there are no obstructions in the supply lines.

Additionally, examine the actuator and control system to verify proper functionality and responsiveness.

It’s also important to review the valve’s installation and operating conditions to confirm its use within specified parameters. If you find any issues during the inspection, consider referring to the manufacturer’s documentation for troubleshooting guidance or contact a certified technician for further assistance.

Safety Measures and Best Practices

Inspecting the valve regularly and following safety protocols will help ensure the proper functioning of the Pi123 Valve. Start by checking for any signs of wear, corrosion, or leakage on a routine basis. This proactive approach can help prevent potential malfunctions and ensure the safety of the system.

Additionally, always follow the manufacturer’s guidelines for installation, operation, and maintenance. Proper installation is crucial to the valve’s performance and safety. Ensure that all personnel working with the Pi123 Valve are adequately trained in its operation and safety procedures. Regularly review and update safety protocols to align with industry best practices and standards.

When conducting maintenance or repairs, always adhere to lockout/tagout procedures to prevent accidental activation of the valve. Furthermore, it’s essential to use the appropriate personal protective equipment (PPE) when working with the Pi123 Valve, such as gloves, eye protection, and appropriate clothing.

Upgrades and Enhancements

Consider incorporating the latest upgrades and enhancements to improve the performance and safety of the Pi123 Valve. By integrating these advancements, you can ensure that your valve operates at its best and adheres to the highest safety standards.

Here are some key upgrades and enhancements to consider:

- High-Performance Seals: Upgrading to high-performance seals can improve the valve’s reliability and longevity, reducing the risk of leaks and enhancing overall performance.

- Digital Monitoring Systems: Implementing digital monitoring systems allows for real-time tracking of valve performance, enabling proactive maintenance and better safety management.

- Enhanced Actuators: Upgrading to enhanced actuators can improve the responsiveness and precision of the valve, leading to better control and operational efficiency.

- Advanced Corrosion Resistance Coating: Applying advanced corrosion resistance coatings can significantly prolong the lifespan of the valve, especially in harsh operating environments.

Future Innovations and Developments

Explore the potential for future innovations and developments to further enhance the performance and safety of the Pi123 Valve.

One exciting area of development is the integration of advanced materials. Research into high-strength, corrosion-resistant alloys or composite materials could lead to valves that are even more durable and reliable, particularly in harsh operating environments.

Additionally, advancements in smart technology offer the potential for valves to become more interconnected and responsive. Imagine a Pi123 Valve equipped with sensors and wireless communication capabilities, allowing for real-time monitoring and automatic adjustments to optimize performance and prevent issues.

Furthermore, ongoing research in fluid dynamics and computational modeling could lead to improved valve designs that minimize pressure drops and energy loss while maximizing flow control accuracy.

Finally, the exploration of alternative energy sources and environmentally friendly materials may pave the way for sustainable innovations in valve manufacturing.

As technology continues to advance, these potential developments hold the promise of further elevating the Pi123 Valve’s capabilities, ensuring its continued effectiveness and reliability in diverse industrial applications.

Frequently Asked Questions

Can the Pi123 Valve Be Used in High-Pressure Applications?

Yes, you can use the Pi123 valve in high-pressure applications. It is designed to withstand and effectively control high-pressure environments, making it a reliable choice for various industrial settings.

What Are the Environmental Considerations When Using the Pi123 Valve?

When using the Pi123 valve, consider environmental impact. It’s crucial to assess factors like emissions, waste, and energy consumption. By addressing these concerns, you can ensure responsible and sustainable use of the valve.

Are There Any Specific Regulations or Standards That Govern the Use of the Pi123 Valve in Certain Industries?

Yes, there are specific regulations and standards that govern the use of the Pi123 valve in certain industries. You should familiarize yourself with industry-specific guidelines to ensure compliance and safe operation.

Can the Pi123 Valve Be Integrated With Smart Technology for Remote Monitoring and Control?

Absolutely! You can integrate the Pi123 valve with smart technology for remote monitoring and control. It allows for seamless connectivity, providing real-time data and enabling you to manage the valve from anywhere.

What Are the Potential Future Advancements or Improvements for the Pi123 Valve?

In the future, potential advancements for the Pi123 valve may include improved connectivity for seamless integration with smart technology, enhanced durability for long-term reliability, and advanced monitoring features for real-time data insights.

Conclusion

Now that you’ve learned about the Pi123 valve, you can see how it’s a crucial component in various industries.

Remember, ‘an ounce of prevention is worth a pound of cure’ – so taking care of your Pi123 valve through proper maintenance and understanding its functionality will save you time and money in the long run.

Stay informed about upgrades and innovations to ensure your operations run smoothly.